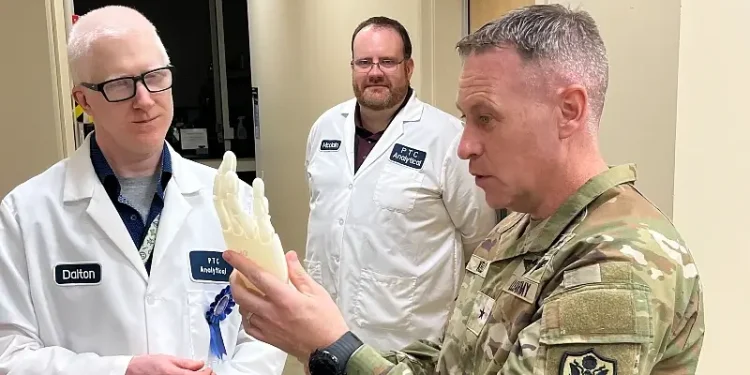

The Defense Logistics Agency (DLA) Troop Support has developed a 3D-printed artificial hand to enhance safety during glove testing for hazardous materials like jet fuel.

This innovation, led by Edward Dalton and Mike McClain, reduces exposure risks and demonstrates the potential of additive manufacturing in military supply chains.

Product Testing

The DLA Troop Support’s Product Test Center Analytical has introduced a groundbreaking method to improve safety in testing gloves designed for handling hazardous substances.

By utilizing a 3D-printed artificial hand, researchers can now test glove integrity without risking exposure to harmful materials such as jet fuel. This advancement not only enhances safety but also streamlines the testing process.

Edward Dalton, a general engineer at the test center, conceptualized the idea after recognizing the significant safety concerns associated with traditional glove testing methods.

Previously, testers had to immerse their hands in jet fuel while wearing protective gloves, posing risks if leaks occurred. The new artificial hand allows for safe and effective testing without direct human involvement.

Advancements in Military Supply Chains

The integration of 3D printing technology into military supply chains is part of a broader effort by the U.S. Department of Defense (DoD) to maintain readiness and technological superiority.

By standardizing additive manufacturing processes across various branches of the military, the DoD aims to enhance operational flexibility and reduce costs associated with producing critical parts on demand.

Benefits of Additive Manufacturing

- Improves safety by reducing direct exposure to hazardous materials during testing.

- Enables rapid production and customization of parts as needed.

- Reduces logistical challenges by allowing on-site manufacturing capabilities.

- Supports economic interests through cost-effective production methods.

This initiative aligns with defense modernization goals aimed at maintaining strategic advantages in contested logistics environments.

The ability to quickly produce and test equipment enhances national security by ensuring that military personnel have access to reliable protective gear without unnecessary delays or risks.

Additional Reading

Wrapping Up

The adoption of additive manufacturing within military operations signifies a pivotal shift towards more efficient and safer practices.

As this technology continues to evolve, it promises further enhancements in operational readiness and cost-effectiveness across various sectors within the U.S. Department of Defense, ultimately strengthening national security efforts.

Sources: Defense Logistics Agency, Defense Logistics Agency, and U.S. Department of Defense.

Prepared by Ivan Alexander Golden, Founder of THX News™, an independent news organization delivering timely insights from global official sources. Combines AI-analyzed research with human-edited accuracy and context.